Bumax is Bufab’s registered trademark, known as the strongest stainless steel fastener in the world. Bumax is manufactured in Bufab’s own plants in Sweden and meets the requirements of high demanding customers when it comes to quality, corrosion resistance, high strength, fatigue strength, traceability and heat resistance. We deliver safety and reliability.

Some of the products in the Bumax- family are completely unique that cannot be found anywhere else on the market. All products have full traceability

(3.1 certificates available for each item) and are sourced solely from premium European stainless steel manufacturers according to rigid specifications.

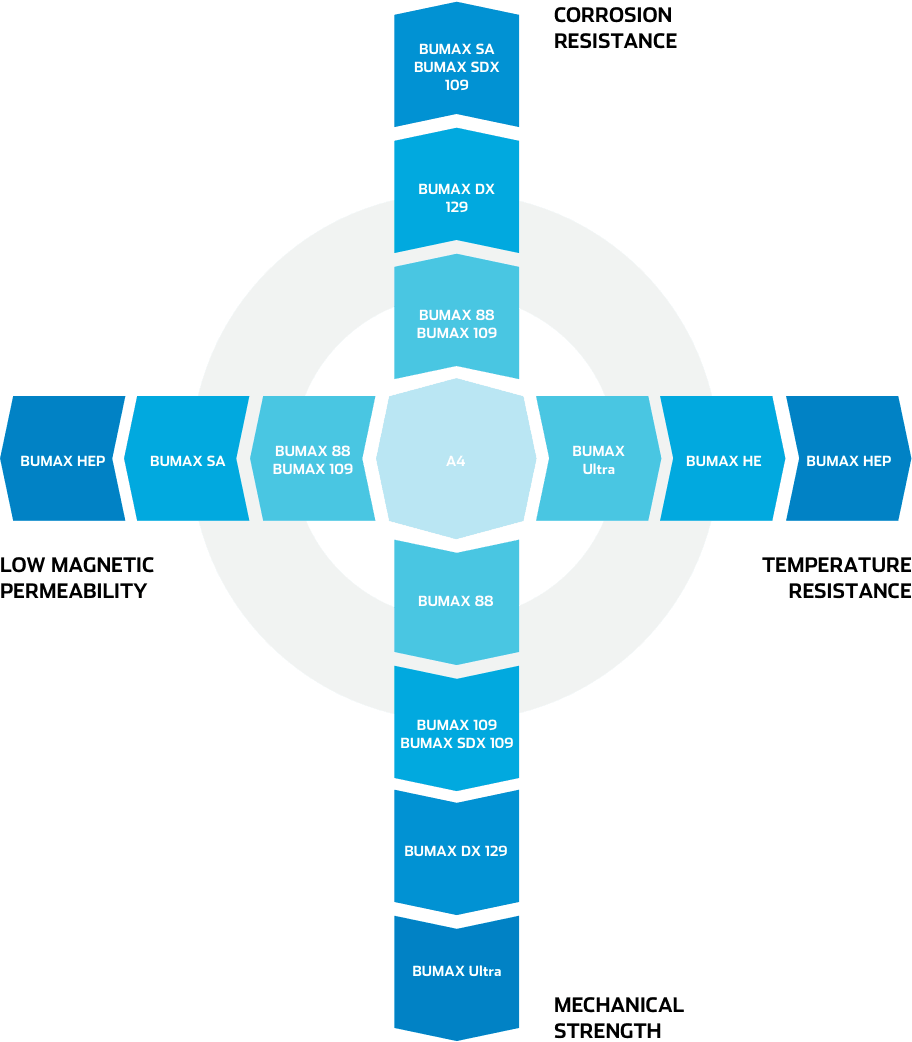

BUMAX® GRADESOther special grades can be offered on request

BUMAX 88 offers better corrosion resistance than standard A4 due to higher molybdenum content. Bumax 88 is a very consistent material that offers higher yield strength and lower amount of inclusion than standard A4 fasteners, that gives superior mechanical properties and fatigue resistance. Bumax 88 fasteners are used in many applications that demands very low magnetic permeability, it has lower magnetic permeability and less variation from batch to batch compared to standard A4 fasteners.

BUMAX 109 is the strongest A4 bolt on the market. Same material as Bumax 88 but higher strength due to special manufacturing process.

BUMAX Nitro, austenitic stainless steel with high nitrogen content, characterized by very high strength and fatigue resistance, in combination with good corrosion resistance. Excellent material for marine application and can be supplied in strength class 12.9 up to M42.

BUMAX Super Austenite (SA), high-alloy austenitic stainless steel for seawater and other aggressive chloride bearing medias. Excellent resistance to general, crevice, pitting and stress corrosion. BUMAX Lean Duplex (LDX) offers economical solution for high strength fasteners in medium corrosive environments

BUMAX Lean Duplex (LDX): offers an economical solution for high strength fasteners in medium corrosive environments.

BUMAX Duplex (DX): This variant is renowned for its outstanding strength, ductility, and fatigue resistance. It also offers good resistance to general corrosion, pitting, crevice corrosion, and stress corrosion. These properties make it suitable for applications where both mechanical strength and corrosion resistance are required.

BUMAX Super Duplex (SDX): SDX takes the mechanical and corrosion resistance properties a step further, providing excellent resistance to general crevice, pitting, and stress corrosion in chloride-bearing environments. Its enhanced performance makes it ideal for more demanding applications than standard duplex grades.

BUMAX Hyper Duplex (HDX): HDX is a groundbreaking alloy designed for the most challenging environments, offering superior resistance to severe corrosive conditions, such as hot chlorinated sea water and acidic chloride media. This makes it particularly well-suited for chemical, oil/gas, marine, and petrochemical industries where these conditions are prevalent.

BUMAX Ultra: Known as the strongest stainless steel fastener available on the market, BUMAX Ultra is a unique precipitation hardenable stainless steel that can achieve ultra-high strength levels. It also provides good corrosion resistance in chloride environments, balancing strength and corrosion resistance for demanding applications.

BUMAX Heat (HE): This variant is designed for high-temperature applications, offering high strength and good oxidation resistance at temperatures up to 700°C. It can be precipitation hardened, enhancing its mechanical properties for applications requiring both high temperature resistance and mechanical strength.

BUMAX Heat Plus (HEP): An advanced version of the BUMAX Heat, HEP is designed to withstand even higher temperatures, up to 815°C. It offers excellent oxidation resistance and superior tensile and creep properties at elevated temperatures, making it ideal for the most extreme high-temperature applications.

CHEMICAL COMPOSITIONNominal wt%

| Grade | Strength, min | Steel | Fastener standard | Micro structure | C max | Cr | Ni | Mo | Other | PRE¹ |

|---|---|---|---|---|---|---|---|---|---|---|

| TS/YS (MPa) | Standard | |||||||||

| BUMAX 88 | 800/640 | 1.4432/36/35 | A4 | Austenitic | 0.03 | 17 | 11.5 | 2.7 | 27 | |

| BUMAX 109 | 1000/900 | 1.4432/36/35 | A4 | Austenitic | 0.03 | 17 | 11.5 | 2.7 | 27 | |

| BUMAX SA | 800/640 | 1.4547, S31254 | A8 | Austenitic | 0.02 | 20 | 18 | 6.2 | N, Cu | 43 |

| BUMAX DX 129 | 1200/1080 | 1.4462, S32205 | D6 | Ferrite-Austenitic | 0.03 | 22 | 5.2 | 3.2 | N | 36 |

| BUMAX SDX 109 | 1000/900 | 1.4410, S32750 | D8 | Ferrite-Austenitic | 0.03 | 25 | 7 | 4 | N | 42 |

| BUMAX SDX NORSOK | 750/550 | 1.4501/1.4410 S32760/S32750 | Norsok M630 MDS D60 | Ferrite-Austenitic | 0.03 | 25 | 7 | 4 | N, W, Cu | 42 |

| BUMAX ULTRA | 1500/1350 | Martensitic | 0.02 | 12 | 9 | 4 | Al, Ti, Cu | 25 | ||

| BUMAX HE | 1000/900 | 1.4980, S66286 | Austenitic | 0.08 | 15 | 26 | 1.5 | Ti, V | ||

| BUMAX HEP | 1000/600 | 2.4952, N07080 | Austenitic | 0.1 | 19 | >65 | – | Al, Ti, Co |

1PRE (Pitting Resistance Equivalent) number shows the pitting corrosion resistance of stainless steels. A higher PRE number indicates better corrosion resistance.

The PRE is defined as, in weight-%: PRE = % Cr + 3.3 x % Mo + 16 x % N

MECHANICAL PROPERTIESin as delivered condition

| Grade | Dimension | Strength Class |

Screws and stud bolts |

Nuts | Washers | ||||

|---|---|---|---|---|---|---|---|---|---|

| Tensile strength Rm, min |

Yield strength Rp0.2, min |

Elongation, min | Stress under proof load, min |

Hardeness, min |

|||||

| mm | MPa | ksi | MPa | ksi | mm | MPa | HV | ||

| BUMAX 88 | M3 - M36 | 88 | 800 | 116 | 640 | 92 | 0.3 d | 800 | 200 |

| BUMAX 88, PED | M6 - M30 | 88 | 800 | 116 | 640 | 92 | 0.4 d | 800 | 200 |

| BUMAX 109 | M3 - M12 > M12 |

109 109 |

1000 1000 |

145 145 |

900 800 |

130 116 |

0.2 d | 1000 | 300 |

| BUMAX Nitro | ≤ M42 | 109 129 |

1000 1200 |

145 174 |

900 1080 |

130 156 |

0.2 d | 2) | 2) |

| BUMAX SA | ≤ M42 | 88 109 |

800 1000 |

116 145 |

640 800 |

92 116 |

0.2 d | 2) | 2) |

| BUMAX LDX | ≤ M42 | 88 109 129 |

800 1000 1200 |

116 145 174 |

640 900 1080 |

92 130 156 |

0.3 d | 2) | 2) |

| BUMAX DX | ≤ M42 | 88 109 129 |

800 1000 1200 |

116 145 174 |

640 900 1080 |

92 130 156 |

0.3 d | 2) | 2) |

| BUMAX SDX | ≤ M42 | 88 109 129 |

800 1000 1200 |

116 145 174 |

640 900 1080 |

92 130 156 |

0.3 d | 2) | 2) |

| BUMAX HDX | ≤ M8 | 88 109 129 |

800 1000 1200 |

116 145 174 |

640 900 1080 |

92 130 156 |

0.3 d | 2) | 2) |

| BUMAX Ultra1) | ≤ M16 | 149 159 169 |

1400 1500 1600 |

203 217 232 |

1260 1350 1440 |

182 195 208 |

0.2 d | 2) | 2) |

1 Bumax Ultra is a grade that is tailor made to solve customer needs in regards of strength, ductility, fatigue and wear resistance. Values in the table are typical strength values, but even higher strength levels can be achieved on some designs and dimension, up to tensile strength levels of 2500 MPa.

2 On request

The data shown in the table are typical and are representative for the majority of standard fasteners. May be subject to alterations, depending on size and design.

PHYSICAL PROPERTIESat 20°C, unless stated otherwise

| Grade | Thermal expansion, mean values in temperature ranges (x10-6) per °C | Magnetic permeability |

|||||

|---|---|---|---|---|---|---|---|

| 20 to 100°C | 20 to 100°C | 20 to 100°C | 20 to 100°C | 20 to 100°C | 20 to 100°C | ||

| BUMAX 88 | 16.5 | 17 | 17.5 | 17.5 | 18 | 18 | 1.006 |

| BUMAX 109 | 16.5 | 17 | 17.5 | 17.5 | 18 | 18 | 1.007 |

| BUMAX Nitro | 15 | 15.5 | 16 | 16.5 | 17 | 17 | 1.003 |

| BUMAX SA | 16 | 16 | 16.5 | 16.5 | 17 | 17 | 1.003 |

| BUMAX LDX | 12.5 | 13 | 13.5 | 13.5 | 14 | 14.5 | 100 |

| BUMAX DX | 12.5 | 13 | 13.5 | 13.5 | 14 | 14.5 | 100 |

| BUMAX SDX | 12.5 | 13 | 13.5 | 13.5 | 14 | 14.5 | 100 |

| BUMAX HDX | 12.5 | 13 | 13.5 | 13.5 | 14 | 14.5 | 100 |

| BUMAX Ultra | 11.5 | 12 | 12 | 12.5 | 12.5 | 13 | 1000 | BUMAX HE | 16.5 | 16.5 | 17 | 17 | 17.5 | 17.5 | 1.007 | BUMAX HEP | 12 | 13 | 13 | 13.5 | 13.5 | 14 | 1.001 |

CORROSION RESISTANCE

| Grade | Urban | Marine, salt water | Hydrochloric acid (HCl) at 50°C | Sulphuric acid (H2SO4) at 50°C | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| High | Low | High | 0.1% | 1% | 2% | 3% | 1% | 10% | 30% | ||

| BUMAX 88, 109 | ◌ | ◌ | 🞇 | 🞇 | ⬤ | ⬤ | ⬤ | ◌ | ⬤ | ⬤ | |

| BUMAX Nitro | ◌ | ◌ | ◌ | 🞇 | 🞇 | ⬤ | ⬤ | ◌ | ◌ | ◌ | |

| BUMAX SA | ◌ | ◌ | ◌ | ◌ | ◌ | ◌ | ⬤ | ◌ | ◌ | ◌ | |

| BUMAX LDX | ◌ | 🞇 | 🞇 | 🞇 | ⬤ | ⬤ | ⬤ | ◌ | ◌ | ⬤ | |

| BUMAX DX | ◌ | ◌ | ◌ | 🞇 | 🞇 | ⬤ | ⬤ | ◌ | ◌ | ⬤ | |

| BUMAX SDX | ◌ | ◌ | ◌ | ◌ | ◌ | ◌ | ⬤ | ◌ | ◌ | ◌ | |

| BUMAX HDX | ◌ | ◌ | ◌ | ◌ | ◌ | ◌ | ◌ | ◌ | ◌ | ◌ | |

| BUMAX Ultra | ◌ | 🞇 | ⬤ | ⬤ | ⬤ | ⬤ | ⬤ | 🞇 | ⬤ | ⬤ | |

◌ No corrosion under normal conditions ⬤ No corrosion under normal conditions

🞇 Possible risk of corrosion, but the steel grade might be suitable depending on requirement, environment, design and maintenance.

Low: Mild condition, such as low concentrations at low temperatures. High: Severe condition, such as high concentrations at elevated temperatures

PRELOAD AND TIGHTENING TORQUE

Preload is needed to keep the jointed part together and function correctly for long periods of time, resisting both static and

dynamic loads.

The combined stresses in the joint should normally not exceed the yield strength of the fastener. In practical use can the

recommended pretension vary between 50-80% of the yield strength Rp0.2. Tightening torque is needed to achieve the necessary preload.

The recommended tightening torque depends on many parameters such as friction, fastener strength, thread diameter, screw

type and tightening procedure. The recommendation used for Bumax products are based on a targeted preload of about 65-70% of

the yield load and a friction coefficient of 0.14-0.16, which can only be obtained by a burr-free surface and using high quality lubrication.

Recommended preload and tightening torque data can be found at www.bumax.se.

All information is strictly informative