Fuller is a preferred distributor for Spirol products.

Spirol Fastening Solutions

Coiled Spring Pins

Coiled spring pins provide flexibility, uniform strength, equal stress distribution, closer diameter tolerances, no interlocking, trouble-free automatic feeding, and they reduce costs. Heavy, standard, and light duty coiled spring pins provide combinations of strength and flexibility to meet your specific engineering objectives. Their shock absorbing design dampens forces and vibration to prevent hole damage and prolong assembly life. Coiled pins have square, burr-free ends and lower insertion forces than other pins, which make them ideal for automated assembly systems.

Available in diameters ranging from .031” (0.8mm) to .750” (20mm).

Contact us for more information.

Slotted Spring Pins

The most appropriate applications for slotted spring pins are in non-critical assemblies manufactured out of mild to hardened steel that are manually assembled. Compressed as it is installed, the pin applies continuous pressure towards the sides of the hole wall. The primary spring action of the slotted pin is focused on the area opposite the gap with the two halves of the pin compressing, or folding, toward the center of the pin as it is installed. Like all spring pins, this allows the slotted pin to accommodate wider hole tolerances than rigid solid pins, which results in reduced manufacturing costs.

Solid Pins & Drive Studs

Solid pins are straight, cylindrical, relatively inflexible press-fit pins. Available with or without a head, they are commonly used to locate components in a fixed position, to maintain alignment, or to act as axles, pivots or hinges. Solid pins are designed to be used in standard drilled holes to minimise manufacturing costs. They are commonly used to replace expensive machined pins. Cumbersome screws are often replaced with drive studs and twist-lok pins that offer better retention and improved assembly speeds.

Knurled pins, drive studs, helical grooved pins, twist-lok pins, and latch pins for plastics are available in diameters from .062” (1.5mm) up to .250” (6mm) as a standard, and up to 2.250” (58mm) upon request. Contact us for more information.

Rolled Tubular Components

Tubular parts not only cost less, but they are often up to 50% lighter than their solid equivalents. SPIROL has proprietary manufacturing technology that enables the cost-effective production of special tubular products that meet the performance requirements of more expensive processes. Configurations include round, oval and “C” shaped geometries. Special features include perforations, notches, chamfers, as well as open, chevron, interlocking, and dovetail seams.

Available in diameters up to 1.500” (38mm) and lengths up to 6.500” (165mm). Contact us for more information.

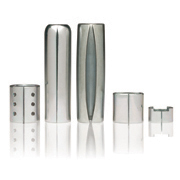

Ground Hollow Dowels

Ground hollow dowels are designed to be a direct replacement for ground solid dowels manufactured per ISO 8734 when used in alignment applications. The main advantage of the ground hollow dowel is its ability to achieve the same alignment as the ground solid dowel with a significant reduction in cost. In most scenarios, the ground hollow dowel is approximately 50% lighter and at least 30% less expensive than the solid equivalent. The dowels can be case hardened for wear resistance or manufactured from heat treated, high carbon steel for improved shear strength.

Available in four standard diameters: Ø8, Ø10, Ø12 and Ø16mm. Contact us for more information.

Dowel Bushings / Spring Dowels

Dowel bushings and spring dowels simplify assembly, reduce weight and significantly lower costs. They are designed to maintain alignment and are used to locate components with respect to each other. These roll-formed, hollow alignment dowels have lead-in chamfers that facilitate insertion into the holes of both mating components. The flexibility of the dowel enables absorption of wide hole tolerances and the staggered seam prevents interlocking.

Dowel Bushings accommodate bolt sizes ranging from #10 to .750” and M5 to M16. Spring Dowels are designed for holes that range in diameter from .250” to .625” and M6 to M16. Contact us for more information.

Spacers

Spacers are commonly used as stand-offs, distance bushings, sleeves, and axles. Typical applications consist of the spacer separating two components in an assembly joined by a bolt, rivet or rod passed through the inside diameter of the component. The inside diameters are designed for a clearance fit with a standard screw or bolt ranging in size from #4 (3mm) up to 1”in diameter (24mm). Stamped, laser-cut and milled spacers are available in thicknesses from .001” to .250” in any flat configuration. Contact us for more information.

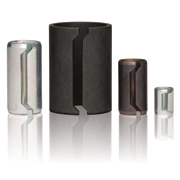

Compression Limiters

Metal compression limiters enable designers to replace housings traditionally manufactured out of metal with plastic. Significant weight and cost savings can be realized, particularly with assemblies that have complex geometries. Metal compression limiters provide “spot” reinforcement of the plastic in high stress joints, or where components mate, enabling the main housing to be manufactured from lower cost plastic. They are designed for easy installation and provide excellent retention and anti rotation.

Pressed-in, molded-in and heat/ultrasonic styles are available for bolts ranging in size from #8 to 3/8”and M4 to M12. Contact us for more information.

Inserts for Plastics

Inserts for plastics allow designers to replace machined and cast metal components with plastic to achieve significant cost and weight savings without any loss of joint strength – even in demanding applications. The use of an insert not only allows the appropriate installation torque to be applied to the screw without stripping the threads, but inserts also ensure that the threaded joint integrity is preserved for the life of the application. They enable unlimited assembly and disassembly of the components without compromising the integrity of the threads.

Heat/ultrasonic, molded-in, pressed-in, expansion and self-tapping inserts are available in thread sizes ranging from 2-56(M2) to 5/16-18 (M8). Contact us for more information.

Precision Machined Nuts

Machined nuts offer many technical and performance advantages over stamped, punched and cold formed nuts. They are tapped 100% square to the face of the part, have defined countersinks, and burr-free threads. Machined nuts assemble easier than alternative products, as the threads roll freely with no “tight” spots; including plated parts. Unlike stamped or cold formed nuts, there is full contact between the face of the machined nut and the host component which assures retention and perpendicularity of the assembled parts.

Finished and heavy hex nuts, jam nuts, machine screw nuts, small pattern nuts, hex and round panel nuts, open and closed cap huts, and knurled thumb nuts are available for thread sizes ranging from 2-56 (M2) to 5/8-27(M16). Special materials and sizes up to 2” across the flats can be evaluated upon request. Available in brass, aluminum and stainless steel. Contact us for more information.

Precision Shims & Thin Metal Stampings

Precision shims are used as compensators to absorb tolerances between mating components. They significantly reduce manufacturing costs as they eliminate the need for each component to be precision machined in order to achieve the proper fit and function of the total assembly. During the assembly process, shims provide adjustment to compensate for accumulated tolerances. This significantly reduces machining and assembly time. Additionally, shims are commonly used to preserve the faces between mating components, thus reducing the required machining time during rebuilding and retrofitting.

Single shims, thin spacers, laminated and edge-bonded shims can be custom-made to customer specifications from a comprehensive inventory of raw materials in thicknesses from.001” up to .250”. Contact us for more information.

Precision Washers

These engineered washers are flat, metal disks with a hole in the middle that have a wide variety of uses. Washers lessen the possibility of damage to mating components and offer a flat space for a nut or bolt to be held securely in place. Other uses are to act as a spacer, wear pad, preload indicating device, or to prevent galvanic corrosion. SPIROL’s Thrust Washers feature less wear and longer life for reduced serviceability costs in a variety of high-wear applications including heavy equipment, automotive, transmission, and industrial power generation. SPIROL produces specialty washers that range in size from a minimum ID of Ø.048” to a maximum OD of Ø48” in thicknesses from .001”up to .250”. SPIROL’s precision washer product line includes thrust washers, compression rings, piston rings and cylinder rings. Contact us for more information.

Disc Spring Washers

Disc springs are conically-shaped components designed to be axially loaded. Due to their predictability, high reliability and unparalleled fatigue life, disc springs are preferred over all other types of springs in critical applications such as safety valves, clutch and brake mechanisms for elevators and heavy equipment, and supports for industrial pipe systems. They can be used individually or assembled into stacks to achieve the desired force-deflection characteristic required for the application. They provide high levels of load / force within a very small space unlike alternative spring-type components which require a significantly larger footprint to achieve the same load.